Introduction

The manufacturing sector is undergoing a revolution, and Extended Reality (XR) is at its forefront. This exciting technology that includes Augmented Reality (AR), Virtual Reality (VR), and Mixed Reality (MR) is shaping the future of manufacturing, promising remarkable innovation and efficiency.

Prepare to expand your knowledge as we present a thought-provoking examination of ‘How Could the Manufacturing Sector Utilize Extended Reality?’ Our article takes a close look at its impact, challenges, and potential solutions. Stay tuned for eye-opening insights!

What are Extended Reality Technologies?

Extended Reality combines real and virtual environments to create immersive experiences. This article explores how these technologies can transform the manufacturing sector, answer your most common questions, and inspire action to embrace these advancements.

Benefits of Extended Reality in Manufacturing

XR Technology for Manufacturing Efficiency

XR is not just a trend; it’s a proven tool that is enhancing productivity, safety, and quality control. By implementing XR solutions, the manufacturing industry can see drastic improvements in various areas:

Virtual Prototyping in Manufacturing

XR allows manufacturers to create digital prototypes, enabling design and testing before actual production. This not only reduces costs but accelerates the development process.

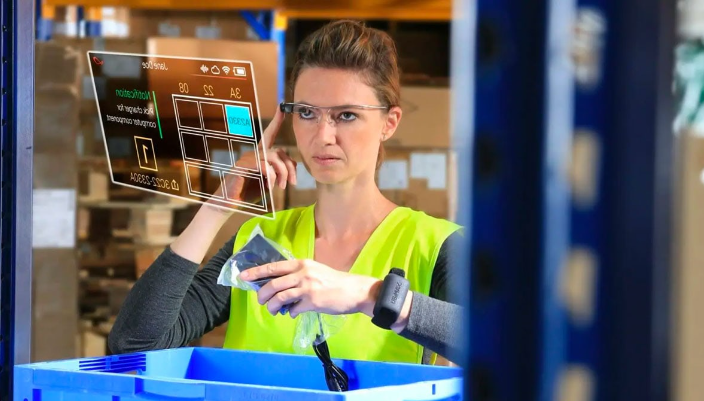

Augmented Assembly Lines

AR can guide workers on the assembly line, offering real-time instructions and reducing errors.

XR-based Quality Control in Manufacturing

Quality control becomes more efficient and accurate with XR. Immediate and accurate analysis leads to better quality products.

Are there any cost-saving opportunities by using XR solutions in the manufacturing field?

Absolutely! XR technologies can significantly reduce downtime, minimize errors, enhance worker training, and lead to overall cost-saving.

XR in Workforce Development

XR Training for Factory Workers

Training workers using VR creates immersive learning experiences. It’s efficient, engaging, and significantly reduces training time and cost.

How can extended reality support workforce training and skill development in manufacturing?

XR can simulate various scenarios, allowing workers to practice without the risk associated with real-world settings. It fosters continuous learning and skill development.

Extended Reality in Supply Chain Management

With XR, managing the entire supply chain becomes seamless. It offers real-time monitoring and optimization opportunities, enhancing decision-making and collaboration.

How does XR-based automation impact the manufacturing supply chain?

XR enables intelligent automation, providing real-time insights and predictive analytics that transform supply chain dynamics.

Immersive Customer Experience

Virtual Factory Tours using XR

Imagine offering your customers virtual factory tours. It’s not science fiction; it’s here! Such immersive experiences foster better engagement and build trust.

Challenges and Future Trends

What are the challenges of implementing XR technology in the manufacturing sector?

Challenges like integration with existing systems, costs, and technology adoption can be overcome with strategic planning and collaboration with experienced technology partners.

What future trends are expected in extended reality for manufacturing applications?

The future looks promising with more intelligent, intuitive, and integrated XR solutions. Automation, remote collaboration, and real-time analysis are just the beginning.

Extended Reality in Production and Maintenance

Virtual Maintenance in Manufacturing

Imagine diagnosing a machine issue remotely or using AR glasses to overlay digital information on real machinery. Virtual maintenance using XR can lead to quicker repairs and less downtime, ensuring that production remains uninterrupted.

How does augmented reality improve quality control and inspection in manufacturing?

AR can provide real-time data and insights to workers as they perform inspections. Superimposing digital information on physical objects allows for precise quality control, leading to more reliable products.

AR/VR-enabled Industrial Automation

Automation is key in modern manufacturing. By utilizing AR and VR in conjunction with AI and robotics, industries can create more flexible and responsive automation systems. These solutions enable real-time monitoring and adjustments, providing unparalleled control over production processes.

XR-based Employee Training in Manufacturing

Virtual Reality for Manufacturing Simulation

VR simulations provide a risk-free environment for employees to learn and practice their tasks. This not only ensures safety but also enables workers to get familiar with procedures and equipment without needing physical access to them.

How can extended reality enhance the customer experience in the manufacturing sector?

Extended reality technologies can offer customers immersive, customized experiences, whether it’s through virtual tours of the manufacturing floor or augmented reality previews of products. This builds deeper connections and trust between manufacturers and their customers.

XR in Design and Collaboration

Extended Reality for Product Design

XR technologies offer designers the opportunity to work in 3D, collaborate in real-time, and see their designs come to life before they’re even produced. This can significantly reduce development times and lead to more innovative products.

Can extended reality help with remote collaboration and communication in manufacturing?

Yes, XR technologies enable seamless collaboration between team members, regardless of their physical location. Whether it’s a design meeting or troubleshooting a production issue, XR allows for real-time communication and collaboration.

Security Considerations in XR Technology

What are the potential risks and security concerns associated with XR technology in factories?

Like all connected technologies, XR can be vulnerable to security risks. Adequate measures like encryption, authentication, and regular updates should be in place to ensure that the information remains secure.

How can the manufacturing industry overcome barriers to adopting extended reality solutions?

Collaboration with experienced XR technology providers, careful planning, investment in training, and focusing on demonstrable ROI can facilitate successful integration of XR into the manufacturing industry.

Best Practices and Tools for XR Integration

What software and hardware are commonly used for extended reality applications in factories?

Utilizing state-of-the-art hardware like VR headsets, AR glasses, and specialized software tailored for the manufacturing industry can lead to successful XR integration.

What are the best practices for implementing extended reality projects in the manufacturing industry?

Understanding the business needs, aligning with strategic goals, investing in training, collaborating with experienced partners, and measuring the results are critical best practices for implementing XR projects.

Extended Reality and Sustainability

How does XR support sustainability in manufacturing?

By optimizing processes, reducing waste, enhancing energy efficiency, and enabling remote collaboration, XR technologies can contribute significantly to sustainability goals in manufacturing.

Frequently Asked Questions on How Could the Manufacturing Sector Utilize Extended Reality?

How can extended reality enhance product design and prototyping in manufacturing?

XR allows for real-time design collaboration, simulations, and virtual prototyping, reducing time and costs.

What types of training programs can be delivered through extended reality for factory workers?

From basic training to complex machine operation, XR can simulate real-life scenarios for effective hands-on learning.

Can extended reality help with remote collaboration and communication in manufacturing?

Absolutely! XR enables real-time collaboration across different locations, bridging gaps, and enhancing teamwork.

Also Read: Reaper of the Drifting Moon

Conclusion

Extended Reality (XR) is not merely a buzzword or a future concept in the manufacturing industry; it is here and now. Its applications are vast, from enhancing efficiency and quality to boosting innovation and customer engagement. By embracing XR technologies, manufacturers are poised to redefine their operations, enhance their workforce skills, achieve sustainability, and elevate customer satisfaction.

To sum it up, this article has delved into the intricacies of “How Could the Manufacturing Sector Utilize Extended Reality?” leaving no stone unturned and empowering you to make informed decisions moving forward.